A skin effect heat tracing system ?

A skin effect trace heating system is a special electrical heating system that is mainly used in industry to maintain or increase the temperature of long pipelines. This system utilizes the phenomenon of the skin effect, where alternating current (AC) at higher frequencies tends to flow near the surface of a conductor, creating resistance and generating heat. Here is an overview of how it works, its key features, and applications

How Skin Effect Heat Tracing Systems Work

1.Skin effect phenomenon: At high frequencies, the alternating current flows mainly on the outer surface (or “skin”) of a conductor and not uniformly over its entire cross-section. This happens because the alternating magnetic fields inside the conductor induce eddy currents that counteract the current flow inside in the conductor.

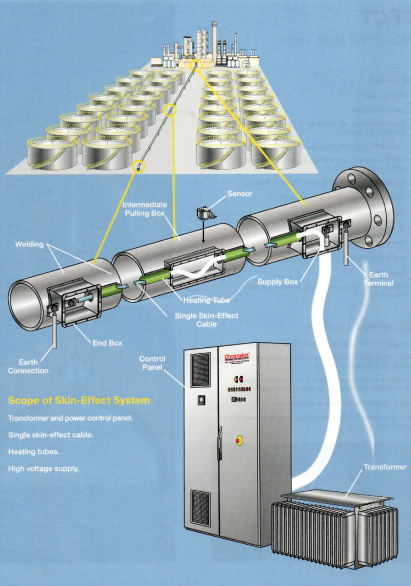

2.System Components

- Ferromagnetic tube: A ferromagnetic tube is normally installed along the pipeline to be heated. This tube acts as the main conductor for the alternating current

- Heating cable: Inside the ferromagnetic tube is an insulated heating cable. This cable is connected to an AC power source.

- Power source: An AC power source, which normally operates at a higher frequency than the usual 50/60 Hz, is used to conduct the current through the heating cable.

- Control systems: Thermostats, controllers, and sensors are used to monitor and regulate the temperature.

3.Heating Process

When alternating current flows through the heating cable inside the ferromagnetic tube, it induces a current on the inner surface of the tube. Due to the skin effect, this current flows mainly on the surface and generates heat due to the electrical resistance of the material. This heat is then transferred to the pipe.

Key Features

- Even heating: Ensures consistent and even heat distribution over the entire length of the pipeline.

- Long heating circuits: Allows very long pipelines to be heated from a single power connection, which is beneficial for industrial applications where heating is required. over long distances.

- High efficiency: Efficiently converts electrical energy into heat with minimal losses.

- Safety: The heating element is enclosed in a tube, reducing the risk of direct contact with electrical components.

- Durability: Designed to withstand harsh environmental conditions, including exposure to chemicals, moisture, and extreme temperatures.

Applications

- Pipeline temperature maintenance: Used to maintain the temperature of pipelines that transport temperature-sensitive materials, such as oils, chemicals, and gases.

- Freeze protection: Prevents pipelines from freezing in cold environments, ensuring the flow of materials.

- Industrial process heating: Used in various industrial processes to maintain the required temperature of pipelines and equipment.

- Energy sector: Commonly used in the oil and gas industry to heat pipelines, especially in remote and harsh environments.

Advantages

- Heating over long distances: Can efficiently heat very long pipelines, reducing the need for multiple outlets

- even heat distribution: Ensures even heating over the entire length of the pipeline.

- High power output: Can deliver a considerable heat, output and is therefore suitable for demanding industrial applications

- Reduced Maintenance: The enclosed design protects the heating elements, reduces maintenance requirements and increases reliability.

Considerations

- Initial Cost: The installation cost can be higher compared to other heating systems due to the specialized components and setup required.

- Complexity: Requires careful design and installation by professionals familiar with the system.

- Control Systems: Requires sophisticated control systems to ensure precise temperature regulation and safety.

Conclusion

Skin effect trace heating systems are a robust and efficient solution for heating long pipe runs in industrial applications. Due to their ability to provide even and consistent heat over long distances they are ideal for maintaining temperature in pipelines that transport temperature-sensitive materials, prevent freezing, and support industrial processes. While they come with a higher initial cost and complexity, their efficiency, longevity, and reliability offer significant benefits for critical heating applications.